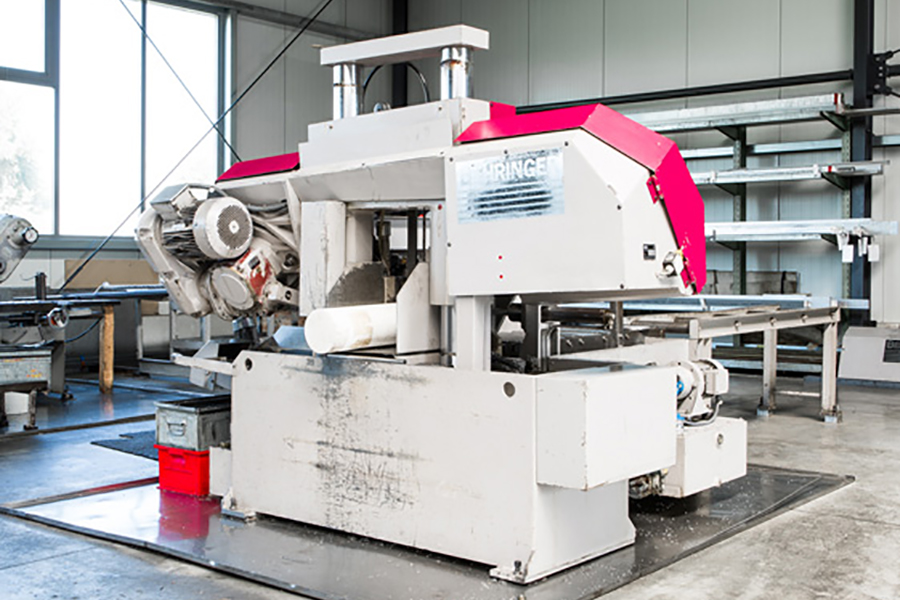

- Automated band saw machines

- Conventional turning lathes

- CNC turning lathes

- Turning/milling centres with counter spindle

- 3-axes machining centers

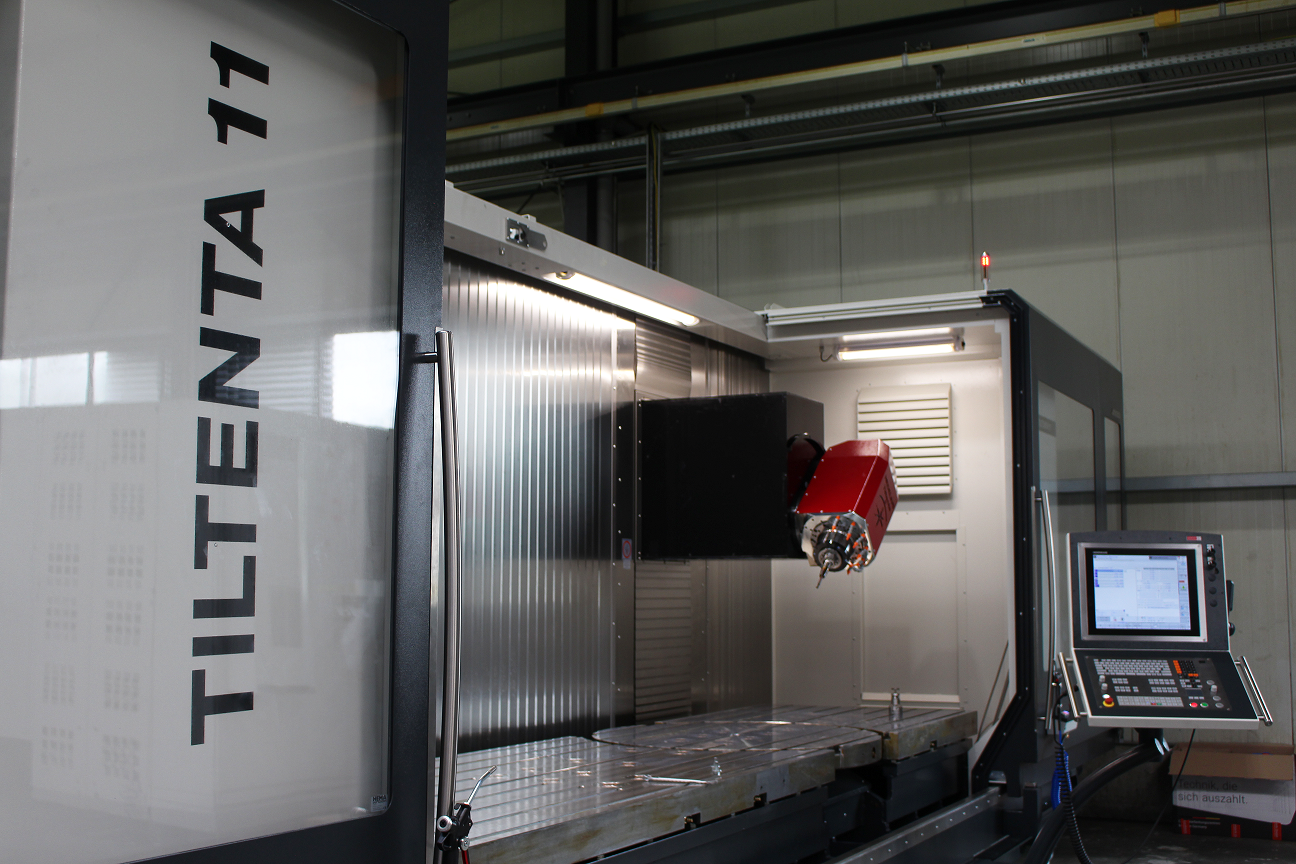

- 5-axes machining centers

- Long bed and moving column machining centers

- Additive Manufacturing / 3D-Printing

- Grinding machines

- Grooving machines

- Measuring devices

- Surface treatments

| Model | Working range | Additional information |

|---|---|---|

| Behringer HPB 220A | Working range < Ø 220 mm | automatic material feed |

| Behringer HPB 303A | Working range < Ø 303 mm | automatic material feed |

EDS_Maschinenbau _Maschinenpark_Drehmaschibe

EDS_Maschinenbau _Maschinenpark_Drehmaschibe| Model | Working range | Additional informationen |

|---|---|---|

| Weiler Praktikant Leit- u. Zugspindeldrehbank | Ø 160 x 500 mm | |

| TUR560 Leit- u. Zugspindeldrehbank | Ø 320 x 1000 mm | |

| TUR630 Leit- u. Zugspindeldrehbank | Ø 380 x 1500 mm | |

| Monforts KNC5 zyklengesteuerte Drehmaschine | Ø 250 x 1500 mm | |

| Monforts KNC8 cycle-controlled lathe | Ø 800 x 3000 mm | Chuck Ø 400 mm Face plate Ø 800 mm Lunette < Ø 600 mm |

| Model | Working range | Additional information |

|---|---|---|

| 4x Monforts RNC3 | Ø 200 x 500 mm | 2 x with powered tools and bar feeder, Ø 42 |

| Monforts RNC4 Hochleistungsdrehmaschine | Ø 250 mm x 600 mm | |

| Monforts MNC5 Hochleistungsdrehmaschine | Ø 250 mm x 1250 mm | self-centering lunette Ø 140 mm |

| Monforts MHC Pick UP | Ø 315 mm x 600 mm | powered tools, pallet loading system for work pieces up to Ø 200 x 150 mm |

| Monforts RNC7 Hochleistungsdrehmaschine | Ø 500 mm x 1500 mm | powered tools, self-centering lunette Ø 245 mm |

EDS_Maschinenbau _Maschinenpark

EDS_Maschinenbau _Maschinenpark| Model | Working range | Additional information |

|---|---|---|

| Biglia 470 YSM Drehzentrum | Ø 210 mm x 370mm resp. bar < Ø 65 mm | Main and counter spindle, y-axis 2 x 12 powered tools, removal of finished pieces |

| Biglia 465 Y2 Drehzentrum | Ø 210 mm x 370 mm resp. bar bis Ø 65 mm | Main and counter spindle, 2 y-axis 2 x 12 powered tools, removal of finished pieces |

EDS_Maschinenbau_Maschinenpark_3_Achsen

EDS_Maschinenbau_Maschinenpark_3_Achsen| Model | Working range | Additional information |

|---|---|---|

| 2x Quaser MV184P | 1020 mm x 610 mm x 610 mm | 30 tools |

| Mikron UM710 | 710 mm x 500 mm x 500 mm | 18 tools, CNC dividing head |

| Mikron VC1000 | 1000 mm x 400 mm x 400 mm | 24 tools |

| Alzmetall BAZ35 | 2500 mm x 500 mm x 550 mm | 40 tools, CNC dividing head |

| Alzmetall CS1200P | 1200 mm x 600 mm x 800 mm | 40 tools |

| Chiron FZ15W | 550 mm x 400 mm x 425 mm | 20 tools, pallet changing table |

EDS_Maschinenbau _Maschinenpark

EDS_Maschinenbau _Maschinenpark| Model | Working range | Additional information |

|---|---|---|

| Hermle C22U | 450 x 600 x 330 mm | 55 tools |

| DMG DMC60U | 600 x 750 x 550 mm | 60 tools, pallet changing table |

| DMG DMC60U | 600 x 700 x 600 mm | 60 tools, pallet changing table |

| DMG DMC80U4 | 800 x 1050 x 850 mm | 123 tools, pallet changing table |

| DMG DMF260/7 linear | 2600 x 700 x 700 mm | 60 tools, round table Ø 750 |

| Modell | Arbeitsbereich | Zusatzinformationen |

|---|---|---|

| Alzmetall BAZ35 | 2500 mm x 500 mm x 500 mm | 40 Werkzeuge, CNC Teilapparat |

| DMG DMF260/7 linear | 2600 mm x 700 mm x 700 mm | 60 Werkzeuge stufenloser Rundtisch Ø750 und stufenloser B-Achs-Schwenkkopf +/-110Grad |

| Hedelius Tiltenta T11 | 4600 mm x 1100 mm x 900 mm | stufenloser Rundtisch Ø1140 (Störkreis Ø 1450), stufenloser B-Achs-Schwenkkopf +/-98Grad, Arbeitsraumtrennwand zur parallelen Rüstung und Bearbeitung, Nullpunktspannsystem |

MarkX7 by Markforged for the production of industrially suitable and highly stable components for robotics, automotive parts, functional prototypes and prosthetics, among others.

Assembly space:

330 x 270 x 200 mm (LxBxH)

Printing material:

Onyx – stiff and strong Nylon Micro-Carbon fiber mix

with high chemical resistance and heat tolerance

Onyx FR – a flame-retardant Onyx version

Onyx ESD – a static dissipative safe variant of Onyx

meeting stringent ESD safety requirements

Nylon White – stronger, stiffer, and more reliable than Onyx creating smooth, non-abrasive surfaces

Continuous fibers for reinforcement:

Carbon fibre – applied f.ex. if the component is to replace a former aluminum component

Fibre glas – f.ex. for most robust, yet affordable tools

HSHT fibre glas – for components with aluminiumlike strength and temperature resistance

Kevlar – for very lightweight, durable components that need to resist repeated and sudden loads

| Model | Working range |

|---|---|

| Elb SWBE 06 NPC-K | 600 x 550 x 300 mm |

| Model | Working range |

|---|---|

| Balzat EUV32 | Slot width x slot length 25x200mm |

| Model | Working range |

|---|---|

| Zeiss CNC-Measuring device Eclipse Calypso Software | 700 x 700 x 580 mm |

| Mahr MMQ200 form measuring instrument with motor-driven probe Software Easy Form | Ø 100 x 200 mm |

| 2-axes video measuring microscope, 30-fold magnification, optical probe system | 200 x 100 x 150 mm |

| Mahr surface roughness tester Mp4i | |

| Coating thicknes gauge (Leptoskop) | Fe/NFe combined unit |

The EDS machine park includes various machines and equipment for surface treatment, including:

Miele washing machine

surface finishing machine

Fine calendering device

Blast cabinet (glass bead blasting)

We will help you get on with things

You have any questions about our manufacturing technologies or do you wish to develop a component specifically made to suit your needs?

Do contact us at +49 (0) 2462 998800

or send an email to info@eds-maschinenbau.de